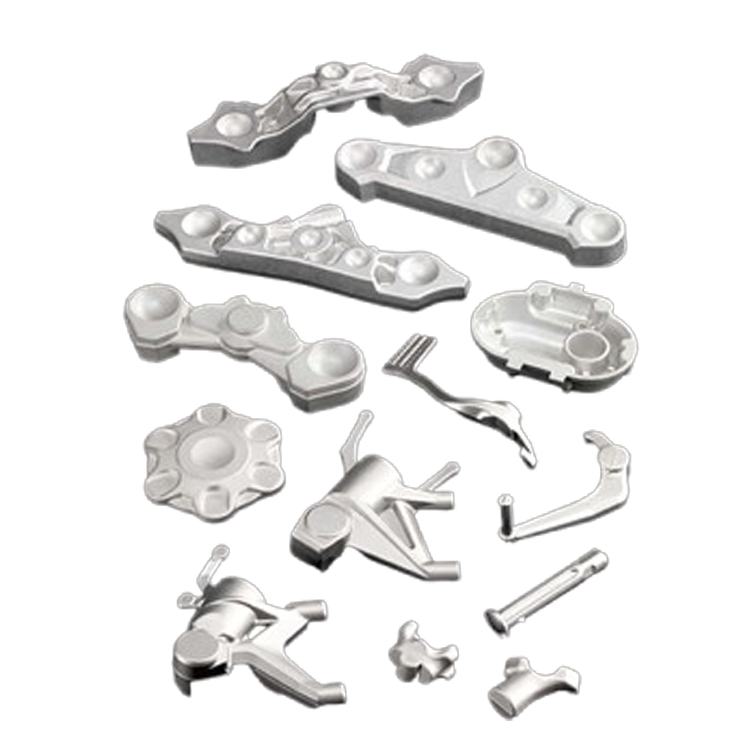

Aluminum Alloy Forging

Core Process for Industrial Hardware

Aluminum is the material of choice in modern motorcycle design for its light weight, strength, corrosion resistance, and thermal conductivity. AFT provides precisionforged aluminum components to motorcycle brands and parts suppliers, including:

Aluminum Materials & Performance Advantages

Forging significantly refines the aluminum grain structure, improving fatigue resistance, heat tolerance, and strength.

Depending on component function and load, we use the following aluminum grades:

6061T6 – Ideal for structural and suspension parts with weldability and durability

7075T6 – Ultrahigh strength alloy for racing and performance bikes

A356 / A201 – Excellent flow and forgeability for complex shapes

ESG Practice

A Model for Sustainable Manufacturing

Choose AFT - Choose Reliability, Safety, and a Green Future.

With the global demand for lightweight, efficient, and sustainable solutions growing, Al Forge Tech Co., Ltd. continues to serve as a key supplier of aluminum forging parts. Whether in manufacturing, defense, medical, or system integration, we offer the most suitable components and solutions.

Environmental

AFT applies green manufacturing standards to deliver sustainable solutions for the motorcycle sector:

- 98% aluminum scrap recovery and full offcut recycling

- Closedloop water system for surface treatments to reduce wastewater

- Transition to solar power and energyefficient lighting at our facilities

- Certified under ISO 14001 and managed according to IATF 16949 quality protocols

As the motorcycle industry advances toward high performance, lightweight, and sustainability, AFT delivers complete aluminum forging and machining solutions. From OEMs to aftermarket and custom performance brands, we are your trusted manufacturing partner.