Aluminum CNC Turning

Aluminum Forging Machining

AL FORGE TECH CO., LTD. has over 30 years of experience in aluminum alloy forging and precision machining, focusing on various industries including automotive, motorcycle, bicycle, medical, aerospace, and industrial hardware. To meet the demand for highprecision, highquality aluminum alloy parts across these industries, the company delivers comprehensive solutions.

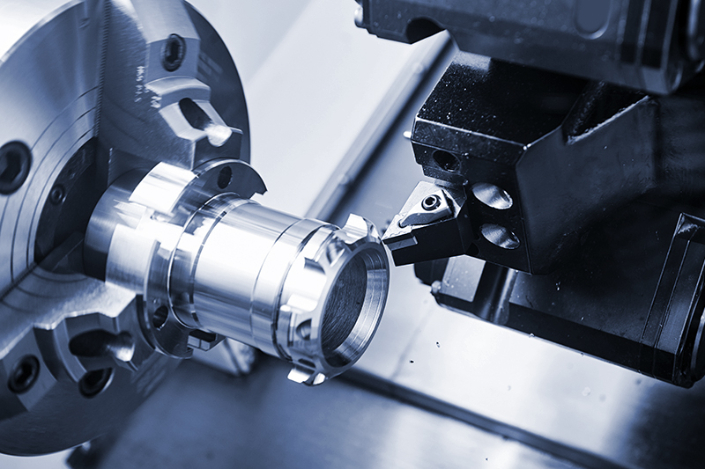

CNC turning is one of the indispensable key processes in aluminum alloy forging, especially suitable for processing round, shaft, and symmetrical workpieces. It forms the foundation for achieving precise geometric shapes. CNC Turning

(Computer Numerical Control Turning)

uses advanced CNC lathes to perform various cutting operations, such as outer diameter, inner diameter, grooves, threads, and end faces on rotating workpieces, achieving highly consistent and repeatable machining results.AL FORGE TECH CO., LTD. invests in highrigidity, highefficiency advanced equipment for CNC turning, such as dualspindle CNC lathes, CNC turningmilling composite centers, and Yaxis multiaxis lathes, specially designed to handle highly complex and highprecision aluminum alloy parts. This technology is widely used in automotive suspension systems, bicycle structural components, and medical connection components.

Example Parts and Geometric Features

Automotive Industry

Lower / Upper Control Arm

The control arm is a key link in the vehicle suspension system that connects the chassis to the wheels, designed to withstand impacts, steering, and vertical loads. Both ends are typically designed as ballshaped or cylindrical structures, requiring CNC turning to achieve concentricity, flat end faces, and consistent hole diameters.

Steering Knuckle

The steering knuckle plays a central role in the wheel steering and suspension system. It contains bearing mounting holes and structures that connect to the steering mechanism. The central hole diameter and multistage outer diameter design require multistep CNC turning to ensure verticality and concentric accuracy.

Upper Mount

As a fixed node between the suspension system and the vehicle body, its mounting surface requires extremely high flatness and parallelism. Face turning is used to achieve the reference plane, followed by inner hole turning to achieve precise fits.

Example Parts and Geometric Features

Bicycle Industry

Shoulder Bracket

A crucial structural component connecting the frame to the fork and headset, featuring a hollow cylindrical structure and multistage tapering design. CNC turning is suitable for processing the inner and outer cylindrical surfaces and positioning shoulders.

Stem

The stem connects the fork to the handlebars, with a hollow cylindrical structure and angled surfaces. Its machining requires high concentricity and multiangle cutting. AL FORGE uses multiaxis CNC lathes to perform multisurface turning in a single setup, effectively shortening the process time.

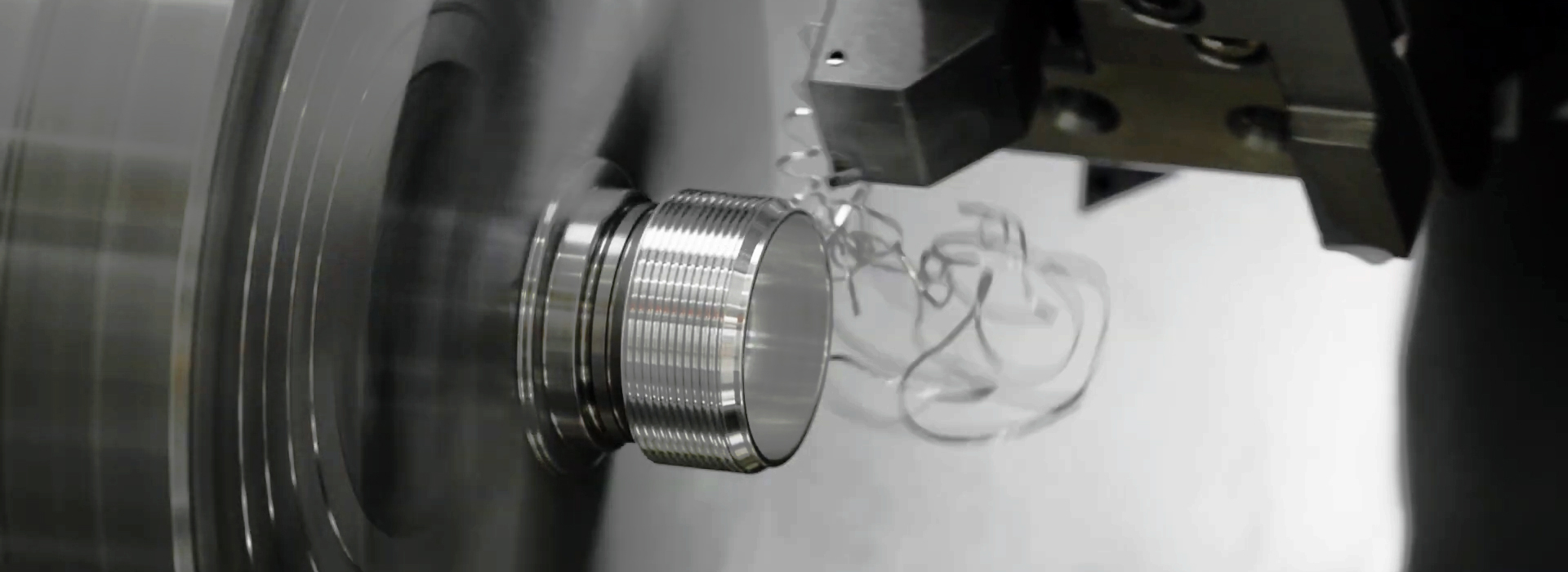

Spline Coupling

A transmission component that requires the outer perimeter to be turned into multiple steps and leave space for the spline. Special tools and multiple feeding cuts are used for this process.

Seat Post

A supporting component installed between the bicycle seat and the frame, with a longstroke hollow tubular geometry. CNC turning is used to complete the end chamfer, radii, positioning shoulder, and threadend machining.

Residual Material Handling and Deformation Control

Since aluminum alloy forgings are close to the final shape, turning operations require rough turning and finishing turning stages to handle the residual material. This ensures that thermal deformation and residual stress do not lead to eccentricity or dimensional instability.

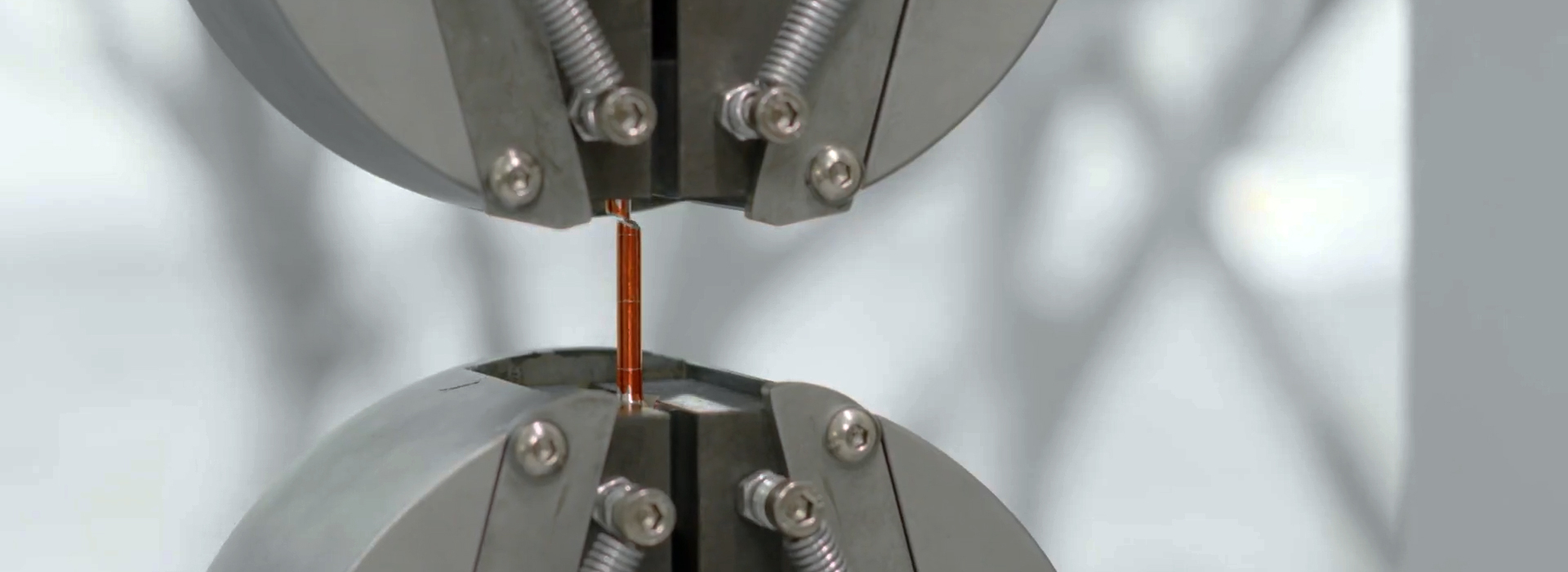

Clamping Design

For noncircular symmetrical structures (e.g., stems, shoulder brackets), custom fixtures must be designed, utilizing hydraulic chucks and soft jaws to reduce clamping deformation and ensure stability.

Tool Selection and Parameter Configuration

AL FORGE uses tungsten carbide and PVDcoated tools to reduce tool adhesion and burr formation on aluminum materials. Spindle speeds are set to over 6000 rpm, with feed rates adjusted based on wall thickness and geometry to maintain a surface roughness of Ra 1.6μm or lower.

Turning Milling Composite Integrated Process

Utilizing the Yaxis and Caxis synchronization control system, hole positions, chamfers, and threads can be processed on the same machine, improving accuracy consistency and saving setup and clamping time.

Quality Inspection and Machining Standards

AL FORGE has introduced online dimensional measurement equipment (such as contact probes and optical measurement systems) and SPC statistical process control. Key parts, such as control arms and steering knuckles, undergo concentricity, outer diameter roundness, and endface flatness analysis to ensure compliance with international automotive standards (such as TS16949) and ISO standards.

Additionally, bicycle parts such as stems and seat posts must undergo strength and torque fatigue tests. AL FORGE has internal simulation assembly fixtures and bending test machines for these purposes.

Manufacturing Advantages

With years of process integration experience, AL FORGE combines the characteristics of forged blanks with CNC turning processes, offering significant advantages when handling diverse geometries and highstrength aluminum alloys (such as 6061T6, 7075T6). Whether for automotive suspension, steering structures, or lightweight bicycle components, AL FORGE provides highperformance, highprecision, and highly consistent CNC turning machining solutions.