Company Profile for Al Forge Tech Co., Ltd. (AFT)

Your Partner in B2B Aluminum Alloy Forging and Machining Solutions

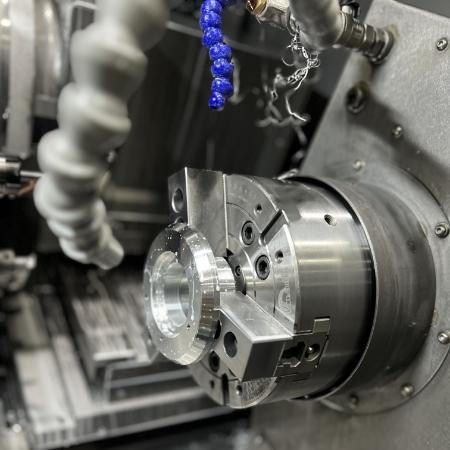

Aluminum Forging Machining Equipment

Main Services

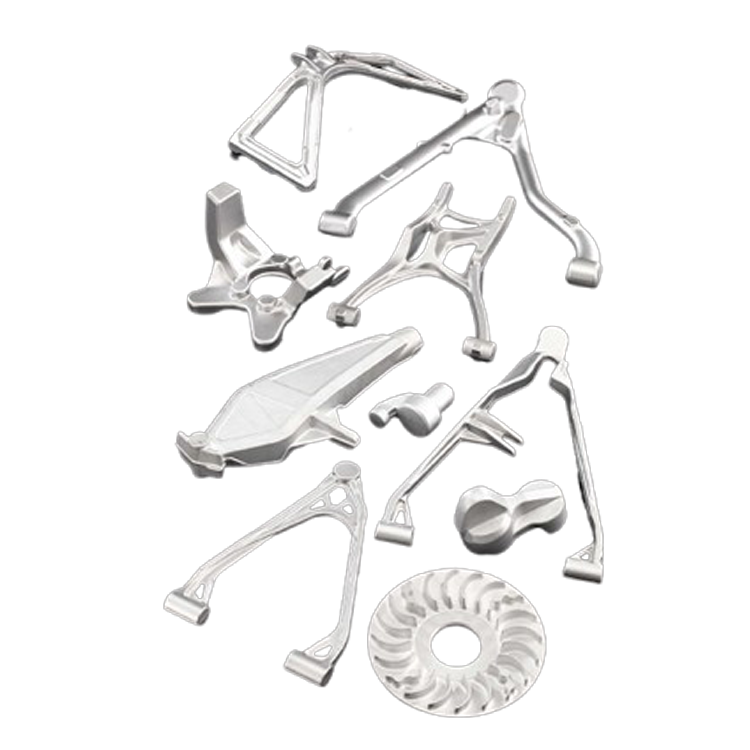

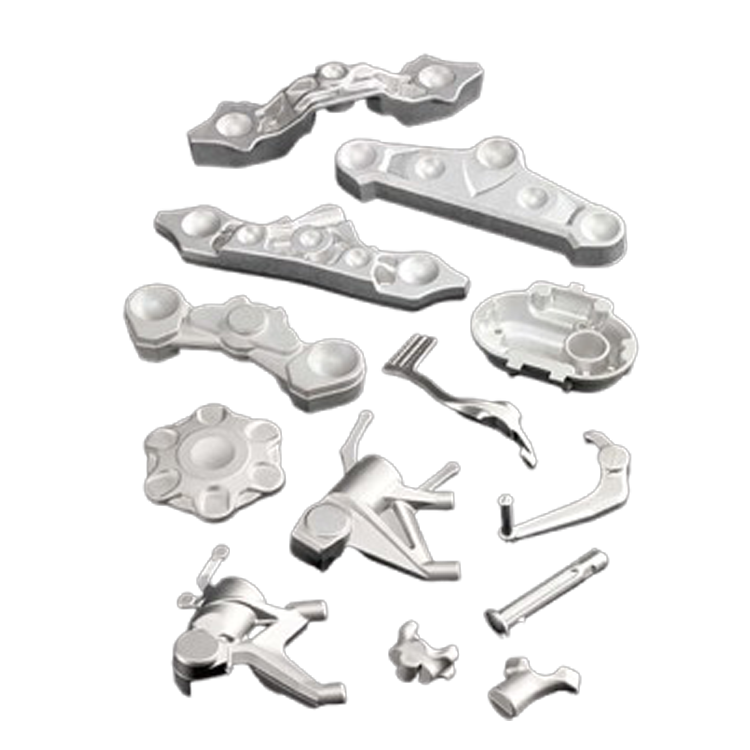

Aluminum Alloy Forging Machining

Aluminum alloy forging is a critical process in the production of highstrength components used in a variety of demanding applications. At AFT, we specialize in aluminum alloy forging machining, offering advanced processes to create components that are designed for durability, performance, and longlasting use. Our forging services are ideal for industries that require highperformance parts with superior material integrity.

Raw Material

Forming

Machining

Quality Inspection

The forging process involves heating the aluminum alloy to a specific temperature and then shaping it using controlled pressure and force. This process improves the material's grain structure, increasing its strength and resistance to wear and fatigue. By utilizing stateoftheart equipment and machinery, AFT ensures that each forged part meets stringent industry standards, making them ideal for industries like automotive, aerospace, and heavy machinery.

Key Benefits of Aluminum Alloy Forging Machining

High Strength and Durability

The forging process creates parts that are stronger and more durable compared to other manufacturing methods, making them ideal for demanding applications.

Superior Material Integrity

Forged aluminum parts have fewer impurities and voids, leading to superior material integrity and reliability.

CostEffective Production

Aluminum alloy forging can be more costeffective in large production runs, as it reduces material waste and enhances productivity.

Customizable Designs

We work closely with our clients to develop customized designs that meet their exact specifications, ensuring that every part is tailored to the specific needs of the project.