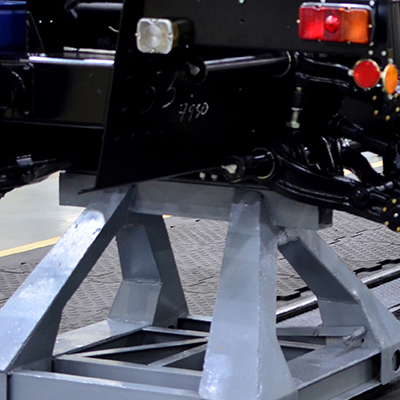

Aluminum Alloy Forging

Core Process for Industrial Hardware

Al Forge Tech Co., Ltd. specializes in aluminum alloy forging and precision machining, offering highstrength, lightweight, and customizable industrial hardware parts. With rigorous process control and years of technical expertise, our forged parts are widely used in industries such as :

Aluminum Alloy Materials

The Golden Balance of Lightness and Performance

In industrial applications, forged aluminum alloy parts are increasingly replacing traditional steel and cast components. AFT's aluminum alloys offer the following advantages

Lightweight (approx. 1/3 the density of steel) : reduces structural weight and enhances efficiency

Excellent corrosion resistance : suitable for outdoor and humid environments

High thermal and electrical conductivity : ideal for heat sinks and electronic assemblies

Anodizable and surface treatable : improves aesthetics and protection

High toughness and ductility : capable of absorbing impact and fatigue

We select optimal alloy grades (e.g., 6061T6, 7075, A356) based on customer application and provide complete material certifications and testing reports.

Application Categories

The aluminum industrial hardware parts produced by AFT include the following categories

Handles & Knobs

Hinges & Latches

Slides & Brackets

Mounts & Feet

Structural Joints

Industrial Pulleys & Shafts

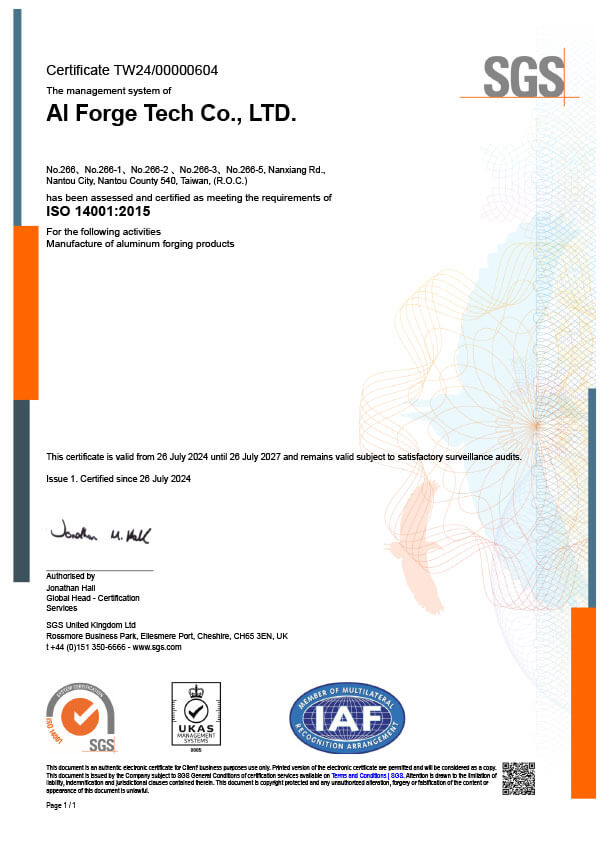

Quality Assurance

Quality Assurance in Line with International Standards

Our production process complies with ISO 14001 Environmental Management and IATF 16949 Automotive Quality Management standards. From material selection to forging, machining, inspection, and delivery, every step is controlled

Full dimensional inspection using Zeiss CMM

Surface roughness and hardness testing instruments

Full inspection reports and material certificates provided for each batch

ISO 14001

IATF 16949

ESG Practice

A Model for Sustainable Manufacturing

Choose AFT - Choose Reliability, Safety, and a Green Future.

With the global demand for lightweight, efficient, and sustainable solutions growing, Al Forge Tech Co., Ltd. continues to serve as a key supplier of aluminum forging parts. Whether in manufacturing, defense, medical, or system integration, we offer the most suitable components and solutions.

Environmental

Increasing the use of recycled aluminum annually

Sorting and reusing forging and machining waste

Implementing water recycling in anodizing and surface treatment

Planning solar system installation to reduce carbon footprint

Social

Regular employee health and safety education

Local sourcing to support regional supply chains

Supporting academiaindustry collaboration and training

Governance

Internal ESG governance committee

Data management and reporting aligned with international standards

Regular audits of ethical and compliant production